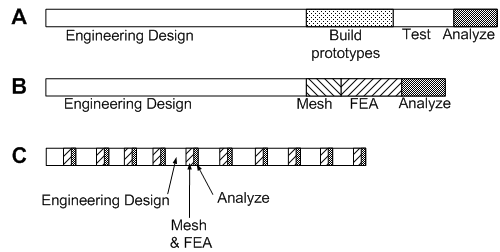

When CAD was introduced, CAD-drawings and later CAD-models were used for making test specimens. After some time it was realized that the models could be meshed and used for FEM analysis making the physical testing obsolete, case B. (This has not completely happened, and will never happen as long as legislation in many countries demands physical tests, such as crash tests).

Unfortunately B has the same drawback as A - the waste of raw material and money. The reason for this is simple: in both cases physical tests and FEA are used at the end of the process to verify the design, not allowing any iterative design loops for reason of time shortage. Findings from FEA were not fed into the design process.

The best method, C, consists of short design & FEA steps. By using modern software such as DesignSpace® from ANSYS, that works in the background of the CAD-program and automatically creates the mesh, the engineer can test and modify the design many times during a single day.

Comparison between different development strategies. A: old-fashioned, B: traditional, and C: modern.